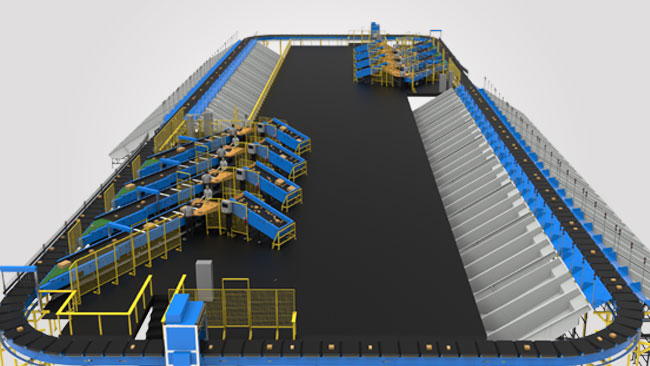

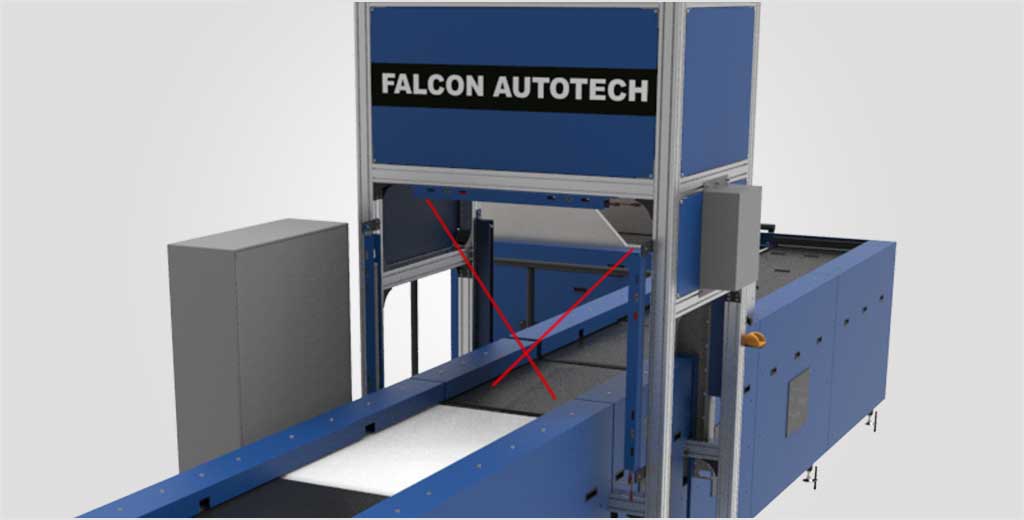

Cross Belt Sorter

THE ULTRA-HIGH SPEED SORTATION SYSTEM

KEY ADVANTAGES

FALCON’S CBS VARIANTS

CORE MODULES OF CROSS BELT SORTER

USP’s OF FALCON AUTOTECH’s CBS

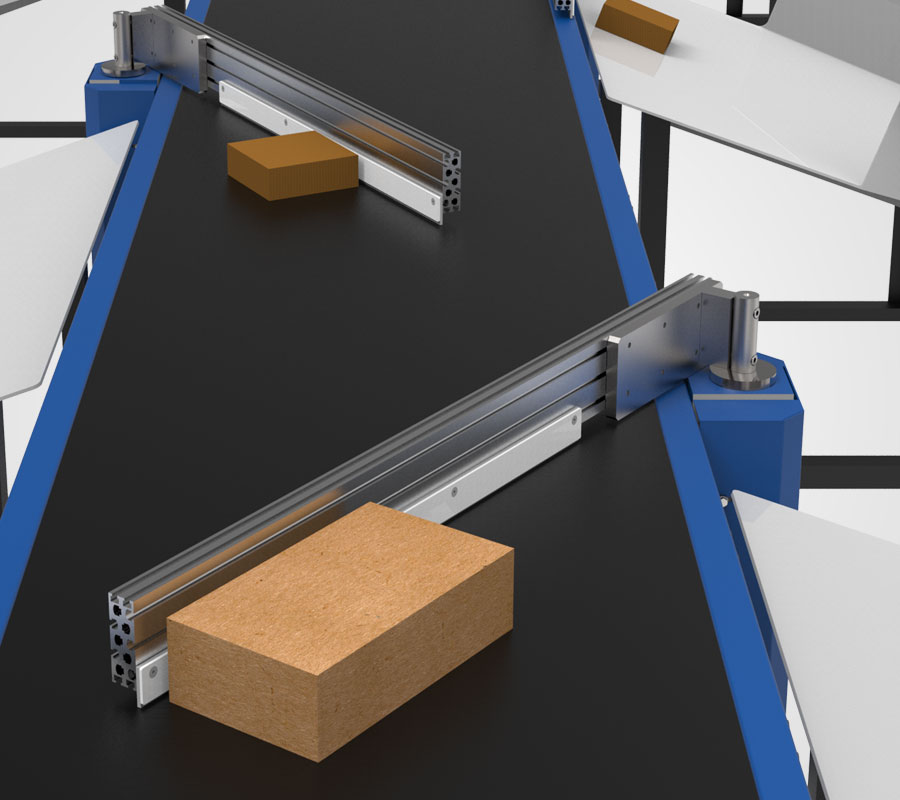

Automatic Item Centering

A premium feature that helps in reducing the chute pitch and achieve predictable discharge trajectories.

Flexible Chute Positioning

CBS Carriers can discharge a parcel anywhere along the track of the sorter, thereby ensuring 100% flexibility in Chute positioning even after the system installation.

High Powered DC Drive Roller

Eliminates the need for complicated drive transfer mechanism and simplifies the system installation and maintenance.

Wireless Data Communication

Wireless Data Communication over latest industrial Wi-Fi standards that results in a simple, economical and high availability system.

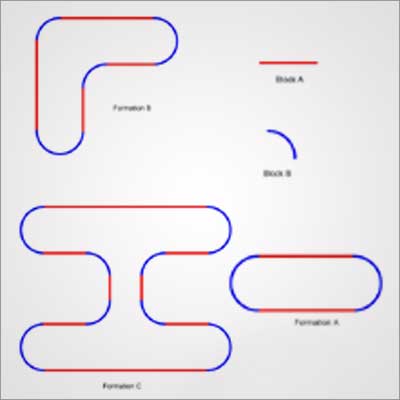

Modularity and Scalability

Simple to assemble modules, enabling super-fast site installations. Plan the system layout in your available facility space by moving around the modules using a basic CAD software.

Real Time Video Coding

Falcon’s RTVC feature remotely decodes the challenging “No-Read Barcode” parcels in real time.

Highest Belt Width

Highest belt widths to carrier pitch ratio can accommodate larger parcels without compromising on throughputs.

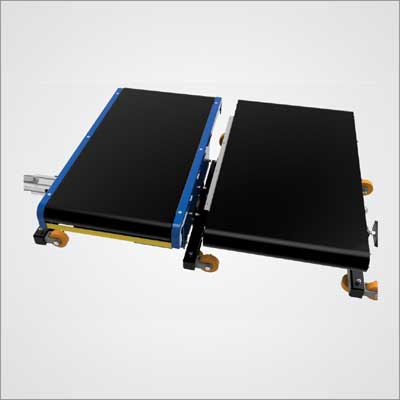

CBS Carrier Chassis

Substantial power savings over a considerable time period due to light weight chassis design of carriers.

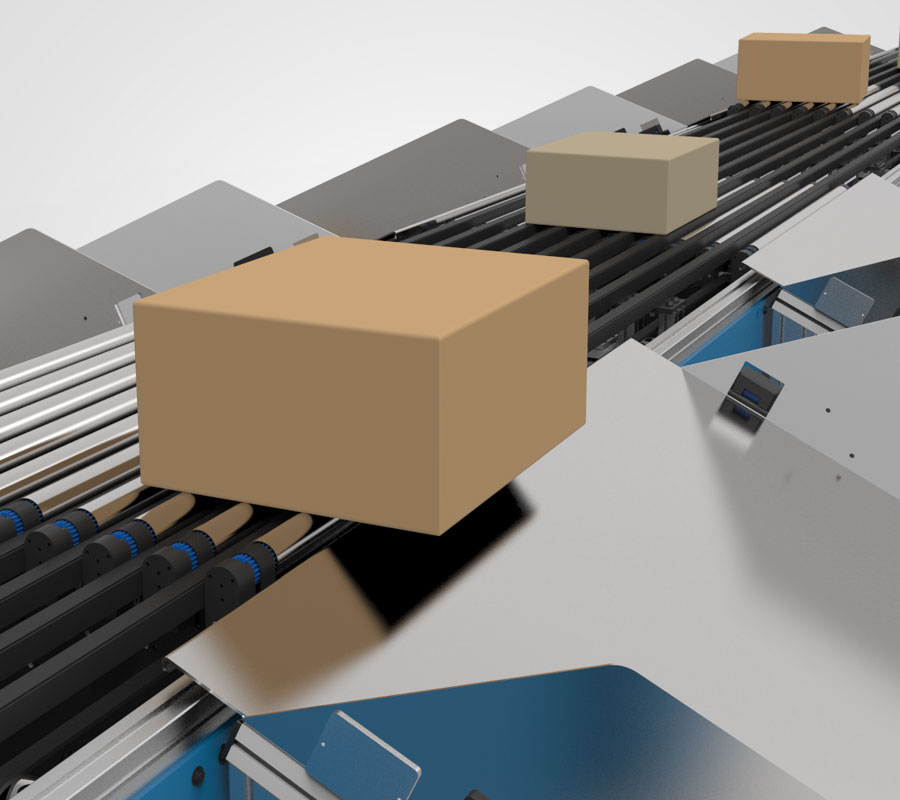

Variable Electric Discharge

Variable Electric Discharge Acceleration depending upon the product profile for smooth product landing.

Linear Motor Drive

Cost effective alternative to LSMs while giving the same benefits of low system noise, low maintenance requirements and high system uptime guarantee.

ADDITIONAL MODULES OF CBS

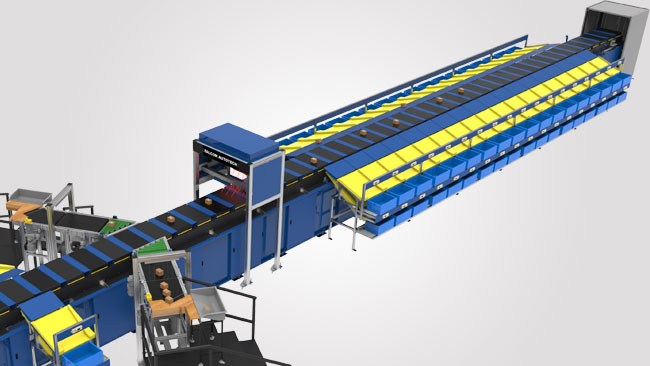

LAUNCH PAD

Operators can drop the bulk parcels on the loading conveyor that slowly pushes the parcels on the orientation conveyor.

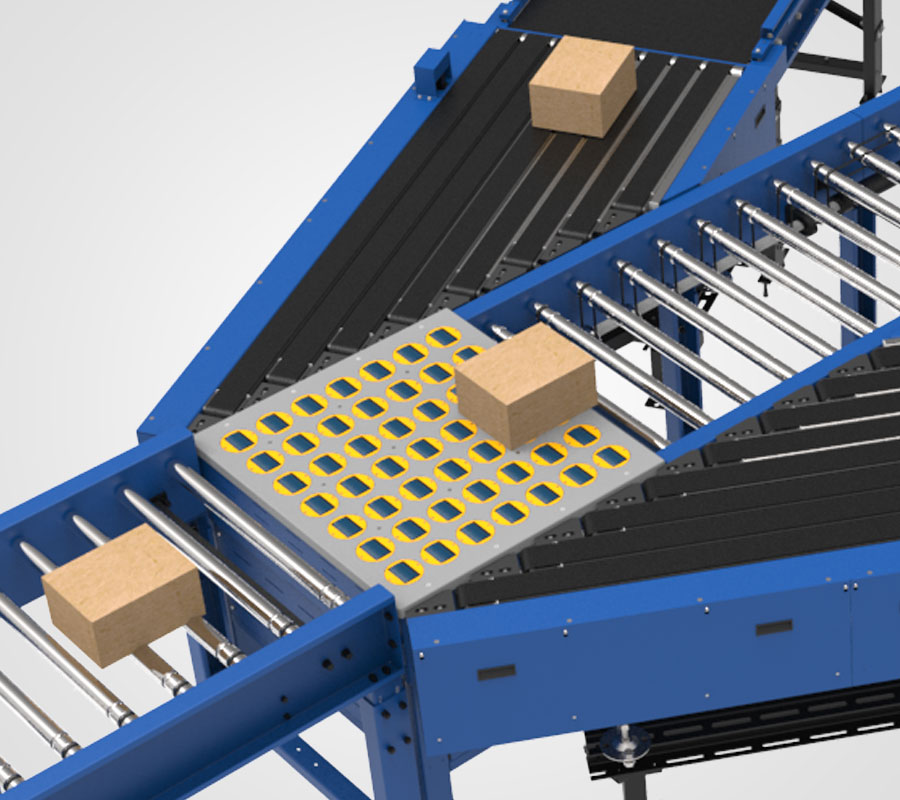

VOLUME DISTRIBUTION SYSTEMS

A system designed with single infeed point to distribute the bulk volume equally ensuring ample availability of parcels at inducts and increase in operator productivity.

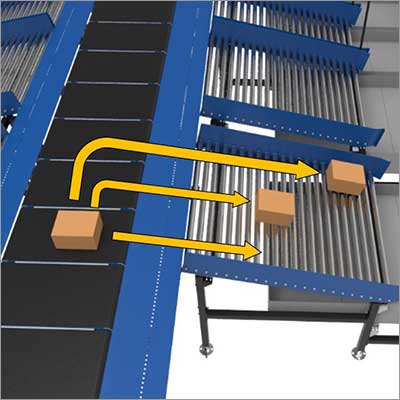

PRE-SORTATION SYSTEM

A unique strategy used to achieve 2x of the designed sorter capacity by segregating the shipments for their respective induct zones mapped to specific end destinations.

DWS System

Falcon Autotech uses most reliable dimensioning and weighing technologies from top global suppliers such as SICK, Mettler Toledo, OCS, etc. Capable of providing dimensioning accuracy of +-5mm and weighing accuracy of +-50 gm at high speed.

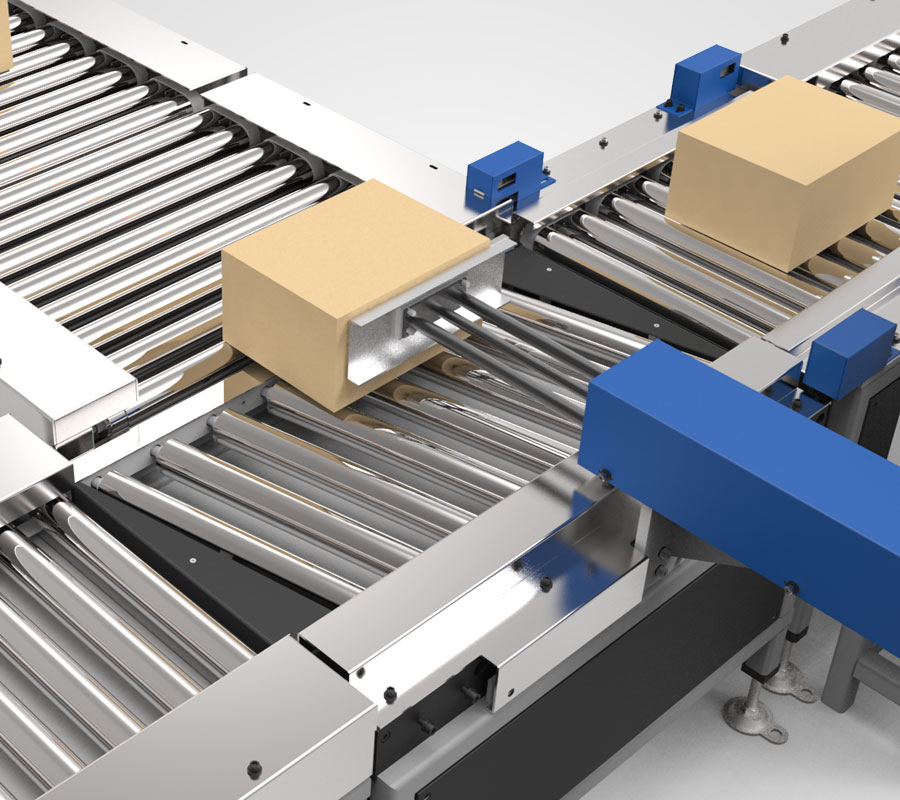

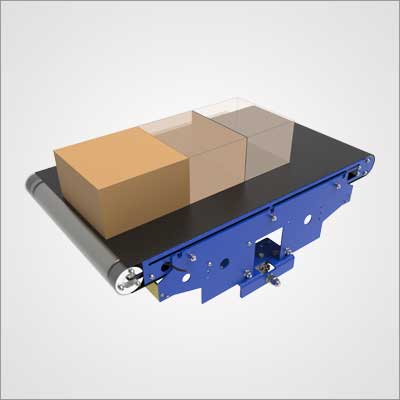

INFEED AND OUTFEED CONVEYORS

Wide variety of powered roller and belt conveyors for moving the shipments to and fro from the docks for complete automation experience.

TAKE AWAY CONVEYORS

Conveyors designed near the end chutes to carry the sorted shipment bags/crates/totes out from the sorting area and freeing the operators to continue their tasks.