Tilt Tray Sorter

THE ULTRA-HIGH SPEED SORTATION SYSTEM

Tilt tray Sorter systems are among widely accepted sortation technologies known for accurately sorting a variety of products. Tilt tray sorters are ideal for sorting centers with need for a high number of sortation destination within limited available space. Falcon Autotech Electrical Tilt Tray Sorters are designed to runs on contactless transmission system which makes it possible to deliver high throughput and maintain minimum noise level. Tilt tray sorter carrier are designed to slide off Parcel/Items into either side of the Tilt Tray sorting conveyor, items can be discharged into Chutes, totes, mail Sacks and Carton Boxes. Tilt Tray sortation systems are not only a good solution for easy future expansion but also provides a long product life with low maintenance cost.

KEY TECHNICAL SPECIFICATIONS

| Property | Tilt Tray Sorter (Loop) |

|---|---|

| Min Product Size Sortable (mm) | 100x100x5 |

| Max product Size Sortable (mm) | 400x600x500 |

| Throughput (Sorts/Hour) | 12000-24000 |

| Max Product Weight Sortable (kg) | 5kg |

KEY ADVANTAGES

CORE MODULES

USP’s OF FALCON AUTOTECH’s Tilt Tray Sorter

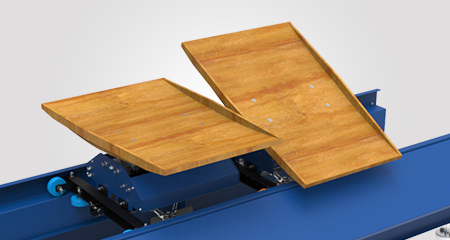

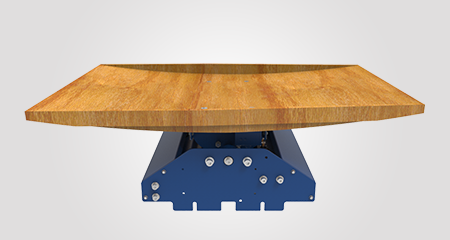

Electric Trays

Use of electric trays ensures simple design and predictable actuation for best sorting accuracy.

Curved Tray Design

The curved design of trays is suitable to handle irregular parcels at very high throughputs.

High Throughputs

Common platform with Falcon’s Tilt Tray ensures same high throughputs as CBS with the advantages of tilt trays.

ADDITIONAL MODULES

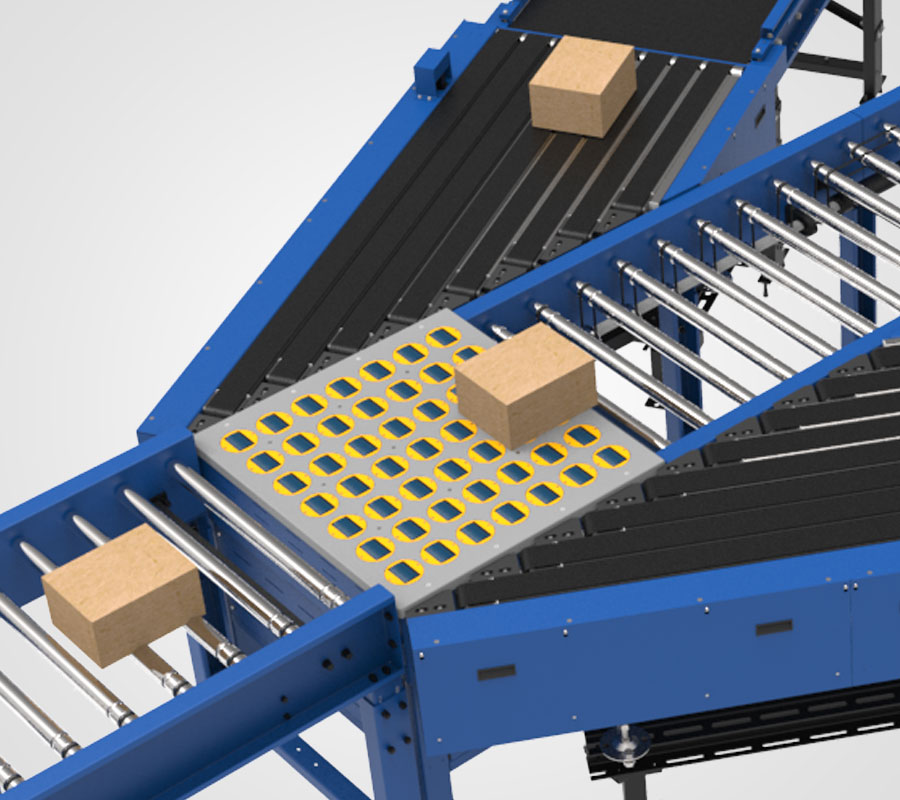

LAUNCH PAD

Operators can drop the bulk parcels on the loading conveyor that slowly pushes the parcels on the orientation conveyor.

VOLUME DISTRIBUTION SYSTEMS

A system designed with single infeed point to distribute the bulk volume equally ensuring ample availability of parcels at inducts and increase in operator productivity.

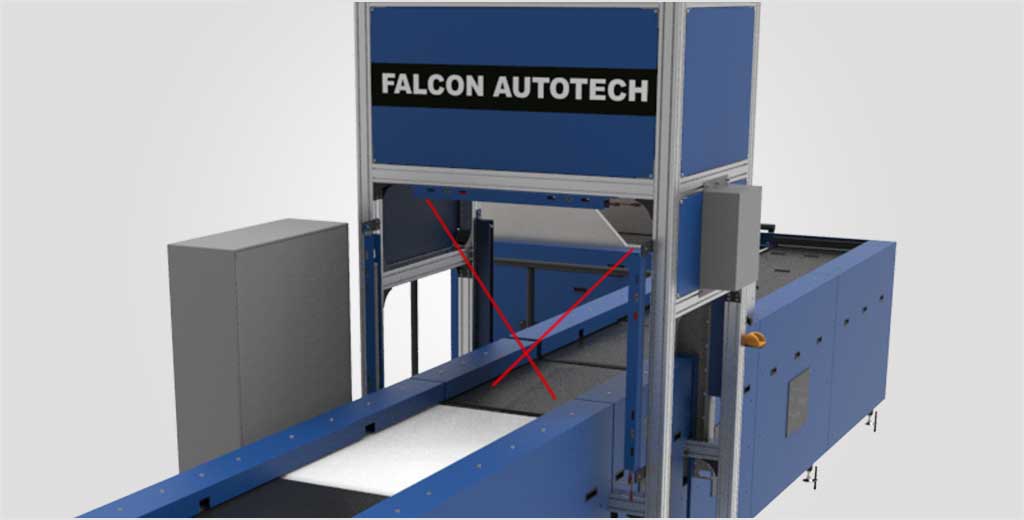

PRE-SORTATION SYSTEM

A unique strategy used to achieve 2x of the designed sorter capacity by segregating the shipments for their respective induct zones mapped to specific end destinations.

DWS System

Falcon Autotech uses most reliable dimensioning and weighing technologies from top global suppliers such as SICK, Mettler Toledo, OCS, etc. Capable of providing dimensioning accuracy of +-5mm and weighing accuracy of +-50 gm at high speed.

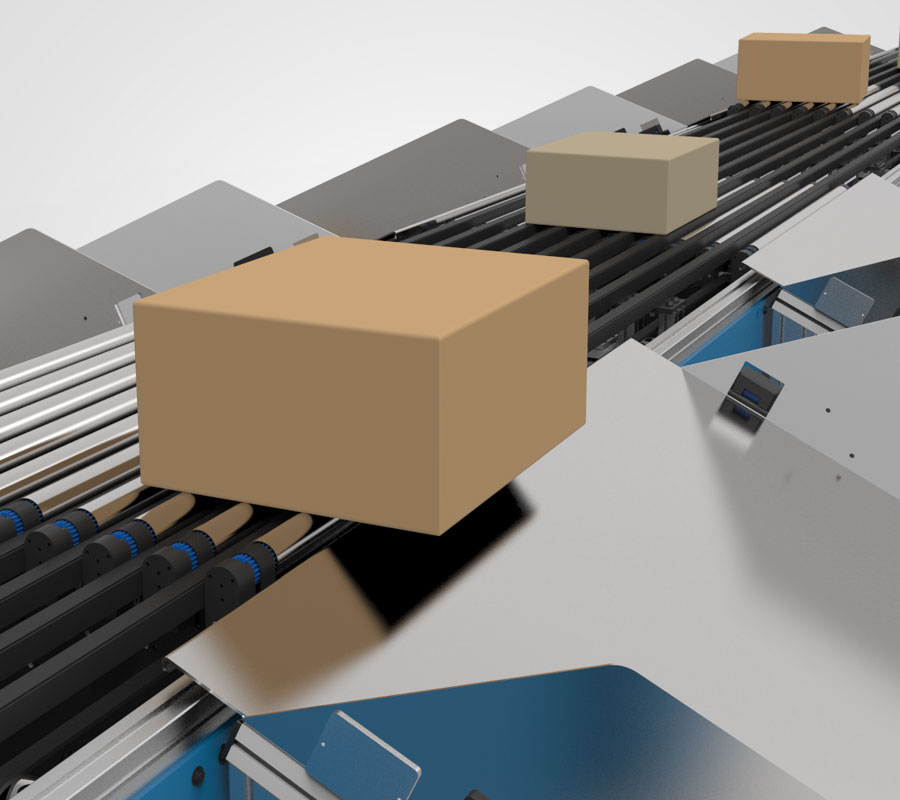

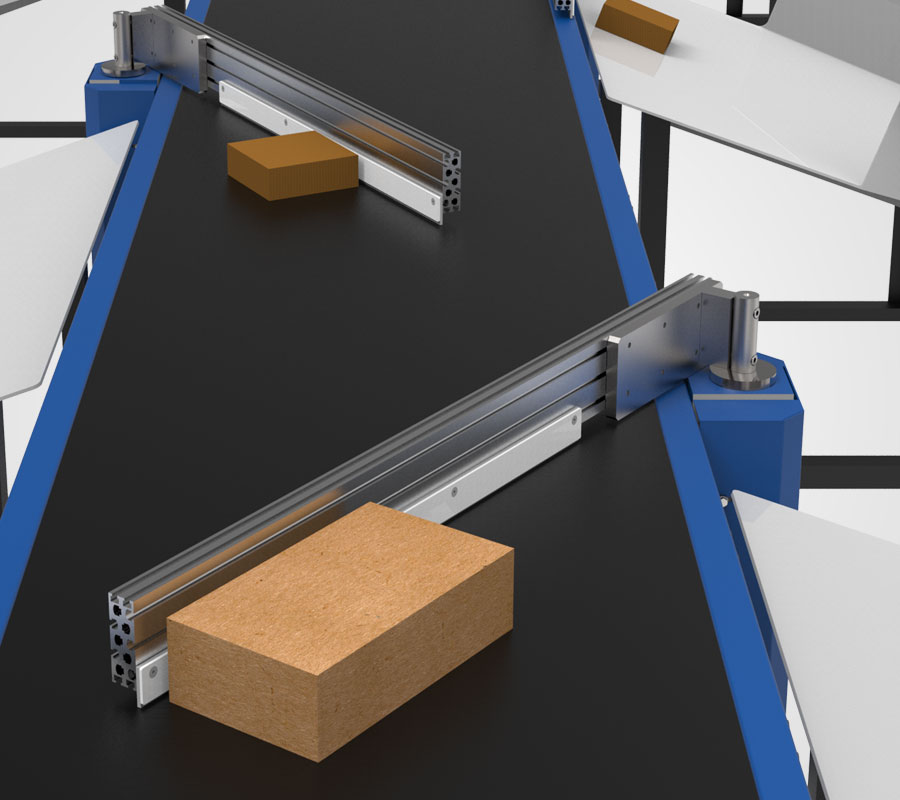

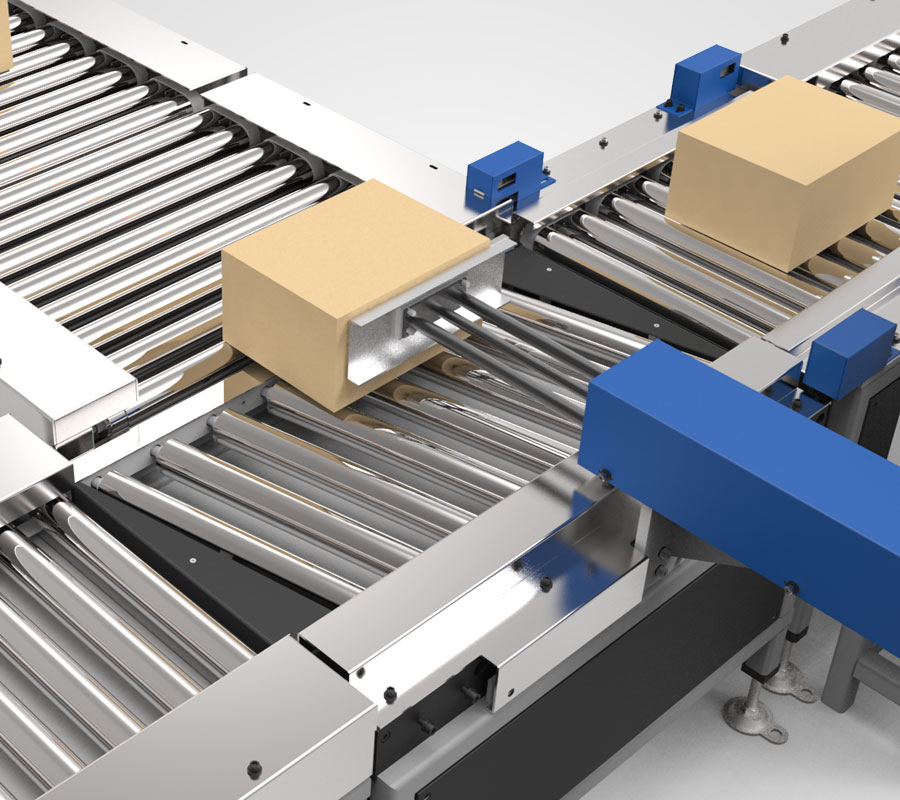

INFEED AND OUTFEED CONVEYORS

Wide variety of powered roller and belt conveyors for moving the shipments to and fro from the docks for complete automation experience.

TAKE AWAY CONVEYORS

Conveyors designed near the end chutes to carry the sorted shipment bags/crates/totes out from the sorting area and freeing the operators to continue their tasks.

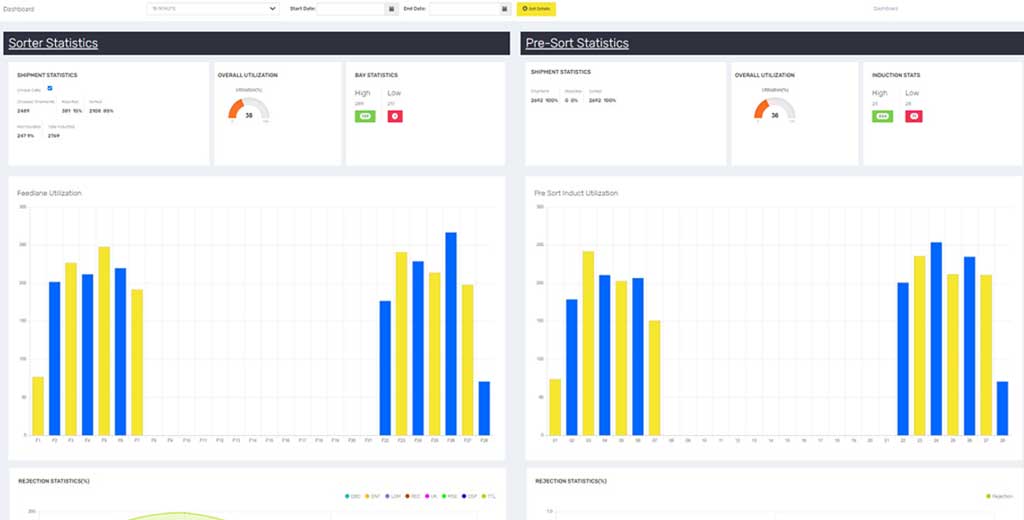

SOFTWARE SUITE

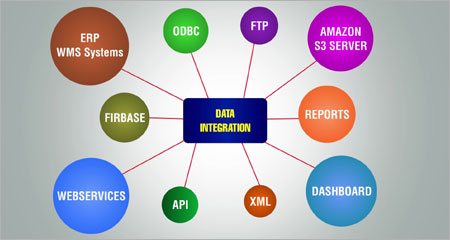

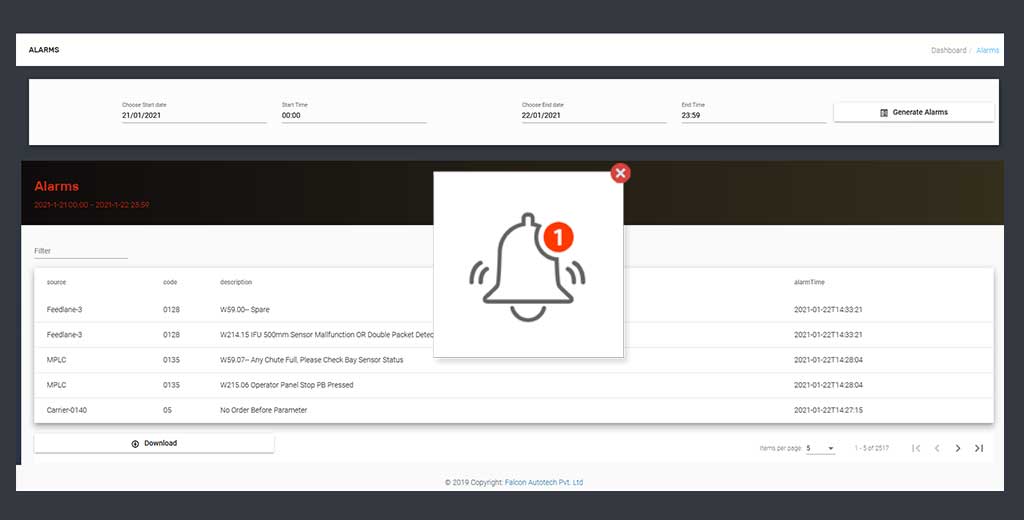

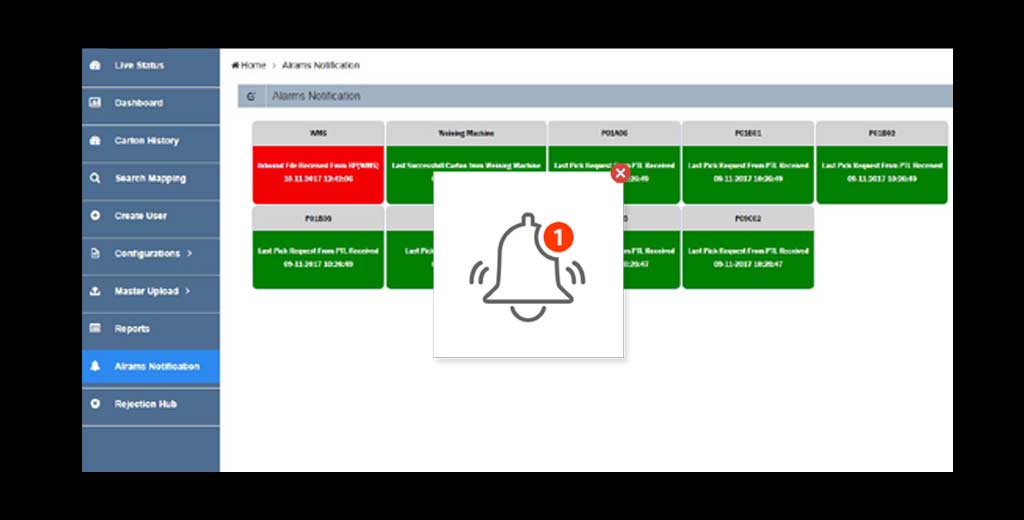

Falcon’s Proprietary SortIT Software is a part of Falcon’s Automation Control Suite (FACtS) that serves as processing engine for communication with the hardware nodes and data exchange with backend ERP/WMS Systems. FACtS offers a carefully curated dashboard customized for each customer and is designed to support all common integration technologies ranging from Web Services, APIs, FTP, ODBC, XML Payloads and many more.

USP OF SOFTWARE

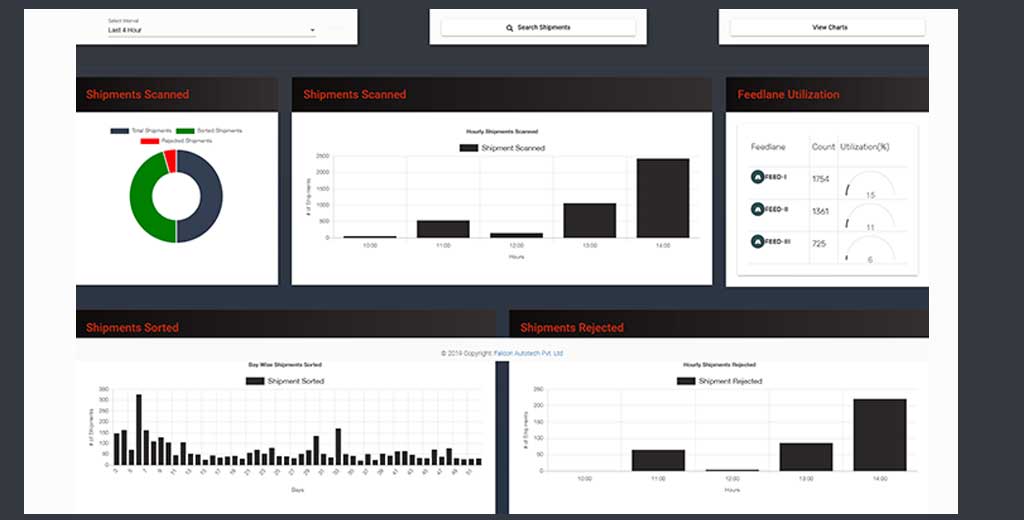

DASHBOARD

Web based dashboard module for remote access to sorter and check live status of operations

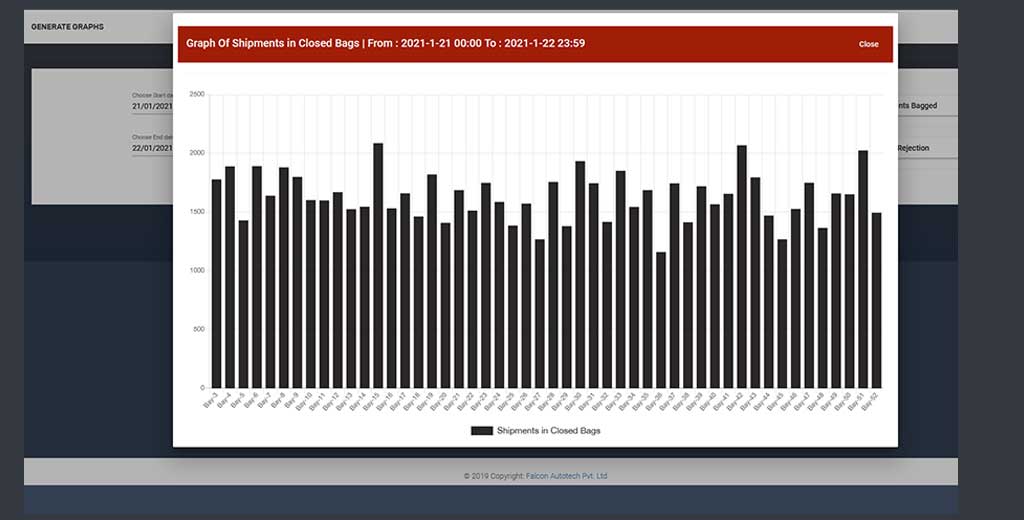

MIS AND REPORTING

Eagle’s Eye View on your operations with Custom Reports right on your Browser, Mobile or tablet. Slice into data to the granularity you want.

USER PRODUCTIVITY ANALYSIS

Manage your workforce better by knowing the Star Performers based on Productivity Data.

DATA INTEGRATION

Secure and easy to setup Communication lines with Host IT systems such as WMS and ERP.

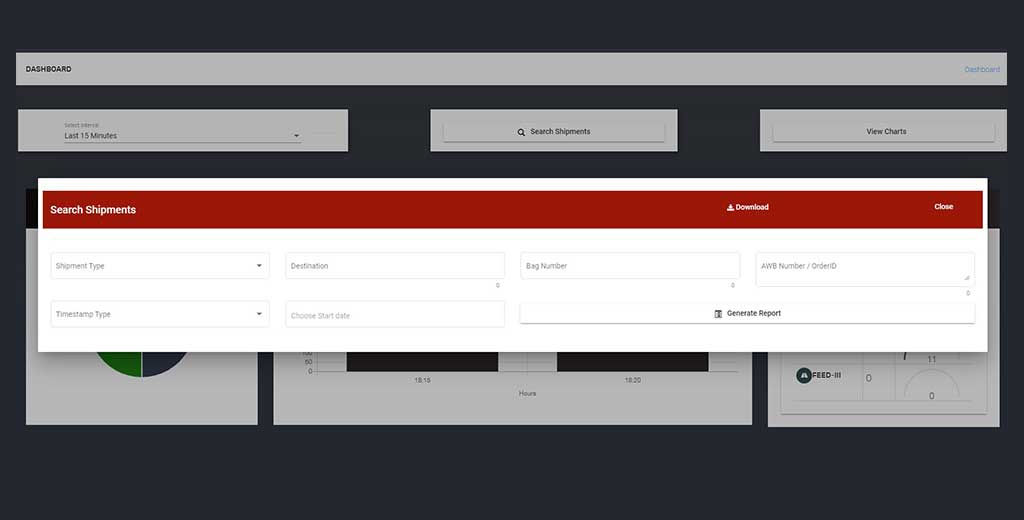

SEARCH SHIPMENTS

To search details of a specific carton/shipment processed on WCS

EVENT ALERTS

Define Custom SMS/EMAIL Alerts on specific events to minimize Downtime and increase worker and resource utilization.

ADD-ON MODULES

Automation Management Systems

AMS is a one of its kind system for predicting and avoiding unplanned down times, maintenance, troubleshooting and efficient spares management System.

Real Time Video Coding

No-Read Barcodes has always been a pain in Sorter Applications globally, With Falcon’s RTVC feature, we can now easily decode such challenging parcels in real time while sitting remotely.

Deep Learning Image Classification

DLIC is advance deep learning algorithms, It can identify objects such as packets on carrier and classify them in different categories.

Image Processing Module

IPM takes images of shipment/cartons, emboss processed data and upload it on cloud storage.

Alert Management System

FAMS facilitates on-site technicians/operators with an android application maintenance task to perform, troubleshooting guides etc.

OTHER SORTATION SOLUTIONS